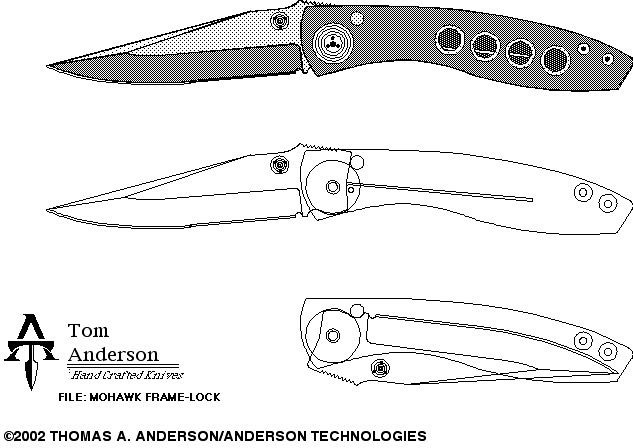

Folder by Tom Anderson

The Drawing

It all starts as a CAD drawing!

Developing Templates

Developing Templates

Templates are made by tracing cut out segments of the drawing onto MicartaŽ, sanding to shape, and drilling the necessary hole locations.

Checking for Proper Template Fit

Checking for Proper Template Fit

Appropriate fasteners are added to ensure the blade and frame templates match perfectly

Layout of the Scales

Layout of the Scales

Using an Ultra-Fine SharpieŽ marker, the titanium sheet is laid out by tracing around the MicartaŽ template.

Sawing the Titanium

Sawing the Titanium

The titanium frame scales are cut on a bandsaw with a bi-metal, 24 tpi blade. A push stick is used for safety.

Preparing for Flattening

Preparing for Flattening

A long doughnut is made from masking tape and attached to the scales to secure them during flattening

Disc Sanding the Frame Scales

Disc Sanding the Frame Scales

The scales are then flattened on a slow rpm disc sander. The masking tape keeps them from slipping from my fingers during sanding

Flattened Scales

Flattened Scales

The scales are flat when the scratch pattern covers 100 percent of the surface. Only the inside faces of the scales are flattened at this time

Squaring the Drill Press

Squaring the Drill Press

Before machining any holes, the squareness of the drill press spindle to the work surface is checked with a precision ground dowel rod and engineer's square

1st Combo Drill

1st Combo Drill

After centerpunching the hole locations, a small combination drill is used to start all holes in the lock side scale (only

2nd Combo Drill

2nd Combo Drill

The larger hole locations are then opened up with a bigger combination drill.

Deburring

Deburring

After each drilling cycle, a countersink is used to deburr all of the holes

Match-drilling the Pivot

Match-drilling the Pivot

After drilling the pivot hole undersize in the lock side scale, both scales are clamped together and the hole location is transferred to the opposite scale

Liner lock folder page 2

Anderson