I have used commercial bandsaw blade steel.

The steel pictured is approximately .073 thick and 8 3/16" wide at the teeth

, 7" wide

at the bottom of the gullet.

and just pictured as typical of what I have

What I have in stock when in stock may vary in different widths and thickness

please before paying for any steel contact me by e-mail to make sure I have this in stock.

sizes are changing all the time so e-mail me to know what you are getting.

I can cut it to any length by but normally I will cut it at 12" for easy of shipping see below

As far as I know the steel will be UDDEHOLM steel, some of the steel still has UDDEHOLM etched on the steel

UDDEHOLM bandsaw blade steel nominal chemical composition

Up to 1,2mm thickness will be UHB-15

C: 0,71% Si: 0,30% Mn: 0,50% P max: 0,020% S max: 0,015%

over 1,2mm thick will be UHB-15N20

C: 0,75% Si: 0,30% Mn: 0,40% P max: 0,020% S max: 0,010% Ni: 2,0%

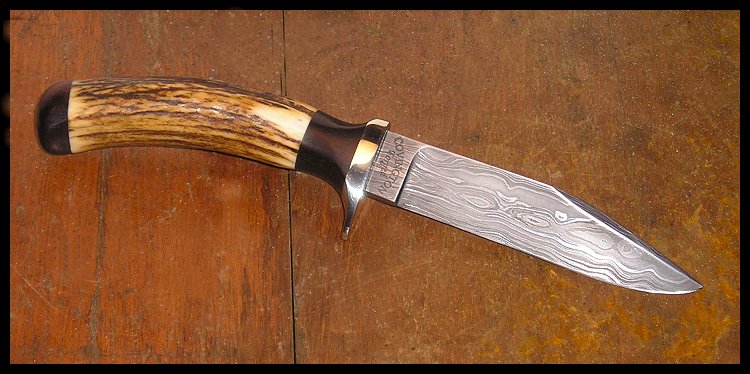

Here is a picture of some 15n20 used in a blade/knife Greg Covington made, alternating 01, (my Band saw blade steel), 1080, and 1084

Below is some twist made from the used 15n20 bandsaw steel By Bill Vining

1084/15n20/nickel

Please note!!

if you want a certain thickness of the UHB15 or UHB15n20

email me to see if it's available.

instrutions and working heats, heat treating is done mostly like O1 would be.

Annealing ,1400-1450F, hold it there for a few minutes then put into ashes or vermiculite so the cooling rate is slowed

Forging 1800-2000F,

Hardening ,1450-1550F

Heat to just above Non-magnetic 1550 F

for at least 5 - 10 minutes,

quench in oil and immediately,

temper at 350 to 400F for at least 1 hour

depending on the use of the blade

Yes, Add this page to my Favorites

© 2004 2008

.