|

Collaboration Knife Project Page 1 |

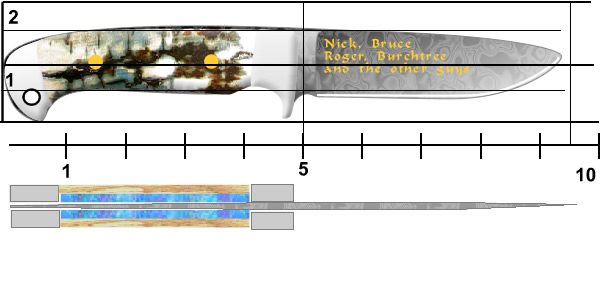

Here is what I have so far, please add or clarify if needed.Bruce Bump:* Etching and technical direction Burchtree Michael Burch:* design, blank profiling and write up itrade Steve Sando:* design and blade finish prior to etching

Nick Wheeler:* Damascus,

presentation edge ddavelarsen Dave Larsen:* blade grind and File work Laredo7mm: Sean Couch * Mokume and Jade John Andrews:* jade, shaping, cutting and drilling Rlinger Roger linger:* HT, edge testing and handle scales Heat treat spec's Dan Gray: * bolsters and take down and handle fit Jay Maines:* sheath pendentive Dan Koster: * Certificate of Origin Harry Knickerbocker:* Bola (from scrap pieces), tang tip, assist Michael with writing E-Mail: all of us here

|

|

Part 1 - Design and Profile

by Michael Burch image created by Steve Sando

|

|

|

|

|

|

Part 2 -Mokume

by Sean Couch |

|

|

|

|

|

Part 3 - Ivory

by Roger & Chuck |

|

|

|

|

|

Part 4 - Damascus

by Nick Wheeler |

|

The billet is of a 1084/15N20 mix

|

|

This is how that billet was made: I start off with between 25 and 33 layers of alternating steels in a stack. They are 1/8" thick, 1" wide, and 6" long pieces of 1084 and 15N20. I MIG weld them together in a stack on the ends and sides, and then weld a handle to the stack. This stack is placed into the forge, running at 23-2400 F. When the stack gets near/into the low orange color range, you take it out and sprinkle anhydrous borax on it. When placed back in the forge, the borax flows over the stack and keeps oxygen away from the surfaces of each piece of steel. After soaking for awhile, I take it all out and very gently squish it under my hydraulic press. After this, the entire stack is a solid piece of steel, in alternating layers. Almost like plywood.

Then it is drawn out in length. At that point, it must be completely ground clean of forging scale/flux

with a 9" angle grinder, cut into short pieces (chop-saw), and restacked/MIG welded. This billet

was 33 layers, drawn out and cut into five pieces. Then at a very high heat, you take the billet out and put one end in a vise. With a huge pipe wrench, you twist the billet. It takes several heats and twists to get it twisted tight and even. After it's all twisted, I forge it out width wise with a special die, and then it's just a lot of forging to get the bar near the proper dimensions.

After a few normalizing cycles, the scale was ground off with that big angle grinder again.

Nick |

|

Part 5 - Jade

by By Sean Couch cut by John, profiling by Roger  |

|

|

|

|

|

|

|

© 2003 - 2007 All Rights Reserved by the makers contributing to this web site . |